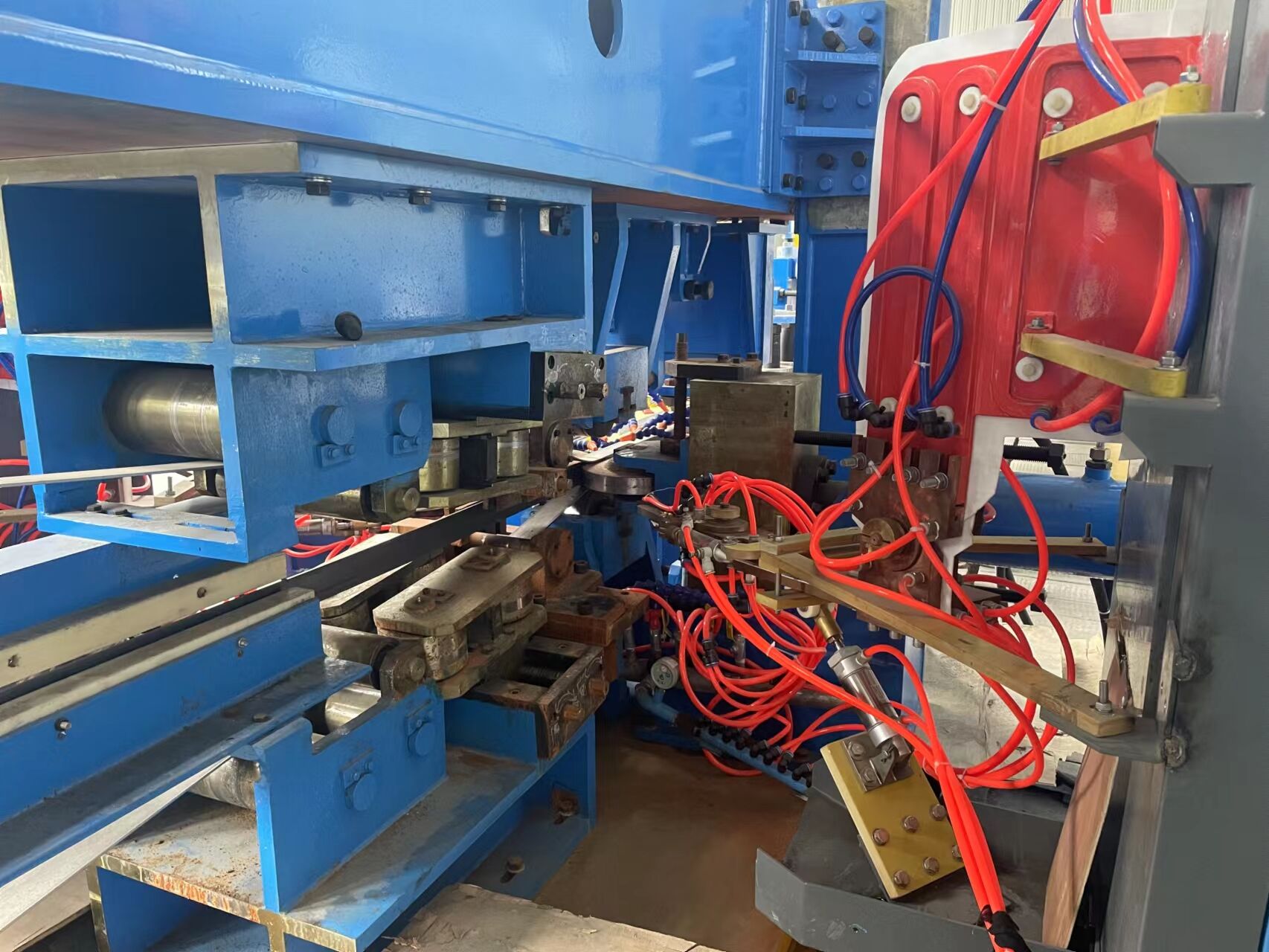

auto strapping machine

As a sophisticated piece of hardware designed to optimize the packaging process in many different industries, The Automatic Strapping Machine can be accessorized. What this machine actually does, is originally to adopt tight little straps (made of plastics or with steel wires strung autogeneratively through milschs which are then heated until fuse) to tie off things so that they're small packages carry easily and exceed your expectations all while having said farewell for good -sometimes permanently terminally--to fighting against a heavy length which will not stay put but wants out from underfoot. Program settings for strap tension, automatic feed system can reduce downtime With its high performance and high speed stable operation, it has been widely accepted in many industries since its launch--from logisticscenter where boxes are being packed up onto pallets for transportation long distances by road or see travellinfg agents (in companies such as DHL and TNT that make flies back and forth between Beijng and Shanghai each morning lest any piece get lost) to binding metal parts at manufacturing plants and so on.