pipe mills manufacturer

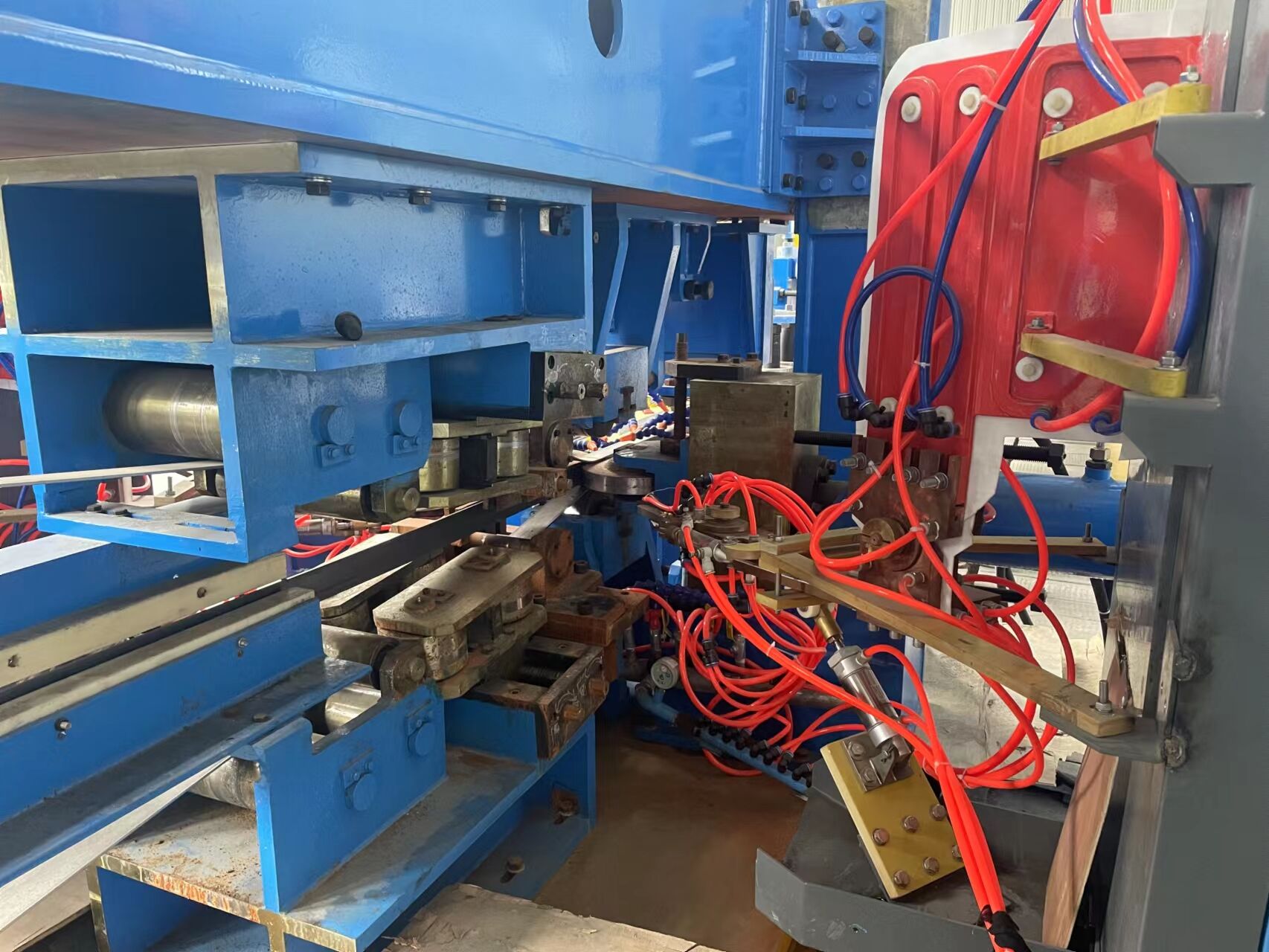

Manufacturers of pipe mills are using the latest techniques today to create high quality steel tubes as a very symbol representing excellence. This month the reporter visited a large Japanese steel company's pipe mill in the port city of Kobe. The functions of the pipe mills are to shape and finishing steel plates into pipes with diameters ranging from 6mm to 750mm. The mills also feature an innovative automated system that will ensure uniformity and high precision in production. In addition there are also technical features such as: computer control numerical processing system(CNC), high speed rolling and welding process which has been designed to keep the requirements of international standards in mind continually These pipes have been used in all industries, including oil and gas, construction, and electricity In not only infrastructure but also energy transportation they are essential parts.