Introduction

Manufacturing is a complex field that requires high accuracy such as cutting metal, plastic, and textiles. Thus, the industries where these are used need them cut to precision, and this is the reason slitting machines are indispensable. In this article, we will be discussing about the introduction of slitting machines, basic components of slitting machines, working of slitting machines, advantages and who need slitting machine in today`s precision manufacturing process.

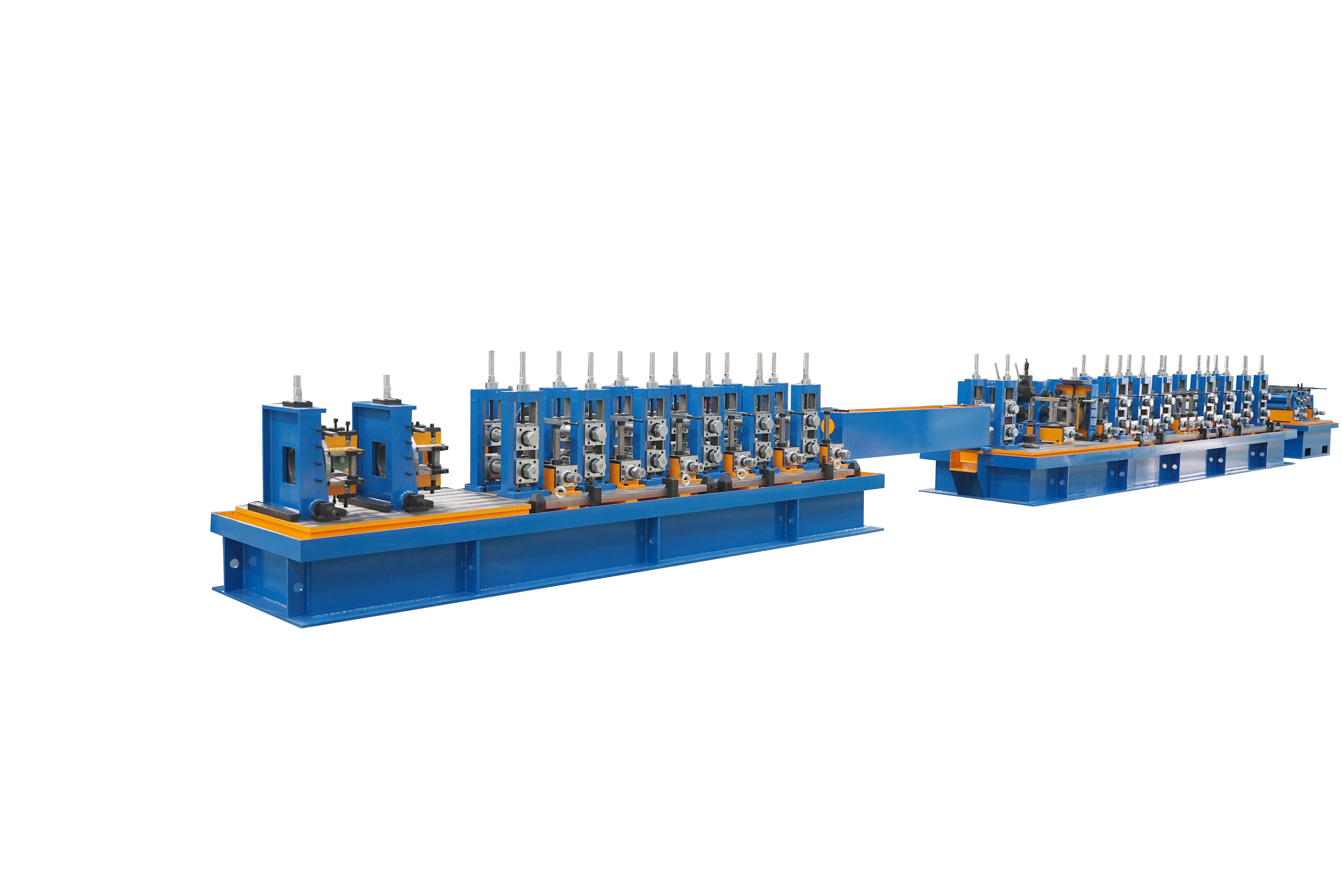

Key Elements and Mechanism behind It

Function of slitting Machines: The Slitting Machines are built around a few essential components tasked with achieving material processing in an accurate and efficient manner. These consist of an facility which feeds the material, a slitter which makes the cuts in the substrate, and a reminder that collects the substrate. In other words a doing machine unroll huge rolls of factor, racks it or mode it down to extra widths, then collects a area down factor in smaller rolls for future uses.

These are razor slitter, shear slitter and crush cutters etc. and each is more suitable for a type of material and use than the others. Knowledge of what is required in your industry leads you to what type of machine you need.

Slitting machine used in different industries

Such industries use slitting machines for precision cutting.

Sheet Metal and Metalworking Industries: The slitting machines cut sheets of metal to different widths for the automotive, aerospace and construction industries.

Plastic And Film:- In this sector, slitting machines are used to cut plastic films and sheets into smaller rolling widths as per the requirements for packing, lamination, further usage, etc.

Paper And Packaging Categories: Paper Or Card Roll For Printing Packaging Roll To Do For Contact Cutter

Textile & Fabric Industries: For cutting the fabric to required widths to be used for garment manufacturing and some other textile applications.

Benefits of Slitting Machines

Lets list some advantages to getting slitting machine benefits:

Splitting Precision and Accuracy: A slitting machine is designed to produce cuts with a high degree of accuracy, which is necessary in order to preserve the high quality of the end product.

Higher Output & Productivity: With slitting automation, the slitting process can run at faster speeds while decreasing manual demand, whether it is time for cutting or the man-power used for the task.

Minimizes Material Waste: Precise Cuts reduces the material waste and thus reduce the cost(both in monetary terms and time) and provide higher level of manufactural sustainability.

Slitting Machine Key Features

Following are some of the main characteristics of the modern plants slitting machines:

Full Capabilities: High-speed shave, shear and crush cutting methods used depending on material and required particle size.

Automation & Computerization Control Systems: It helps in maintaining precision control in the slitting process which in preventing human-made mistakes.

Improved Tension Management and Web Handling Ultra-high-tech tension control systems have taken over the watch of the material throughout the unwind, slitting and rewind on today and machines.

Material and Material Thickness: The reason it is so significant is that the machine must be able to fit the material which you would like to slice.

Slit Width and No. of Slits that is Accessible to the Instrument: The instrument must be able to access the range of slit widths and number of slits which is to be measured.

The speed and the rate of production the machine gives should be matched to the request of the volume.

Cost and return on investment: Expect on various ratio and possible ROI on efficiency improvement and scrap reduction.

Looming on the horizon — New frontiers in slitting technology

Various advancement in Automation concepts developed a solid SOTA (state of the art) technologies which fashion up the Innovations in Area of Industry 4.0 Implications through various technologies available for slitting industry in a few years. This advancement will provide increased energy efficiency, sustainability and precision.

Conclusion

One such machine is the Slitting Machines that is used in the industry for cutting and slitting the materials in a precise manner and plays a major role in productivity and efficiency. With technology developing rapidly, the functions of the slitting machines will also evolve providing spending billions of manufacturing companies with a scope for development and innovation. For those looking to ensure future-readying their business focused and remain ahead of the competitors, it is time for advanced slitting technology only.