Introduction

Steel pipe manufacturing is a highly competitive market with a sharp focus on efficiencies. With the changing landscape of industries, they needed to manage work to optimize workflows. Automation has always been the catchphrase for increasing productivity, reducing costs, and improving operational efficiencies. In this regard of work, the auto steel pipe making machine emerges as one of the strictest innovations. In this article, you will learn how such machines can helps you to transform your manufacturing landscape to achieve the maximum efficiency and profitability.

First, allows us all stay at the starting point to clarify to you the Auto Steel Pipe Producing Machine for Agriculture.

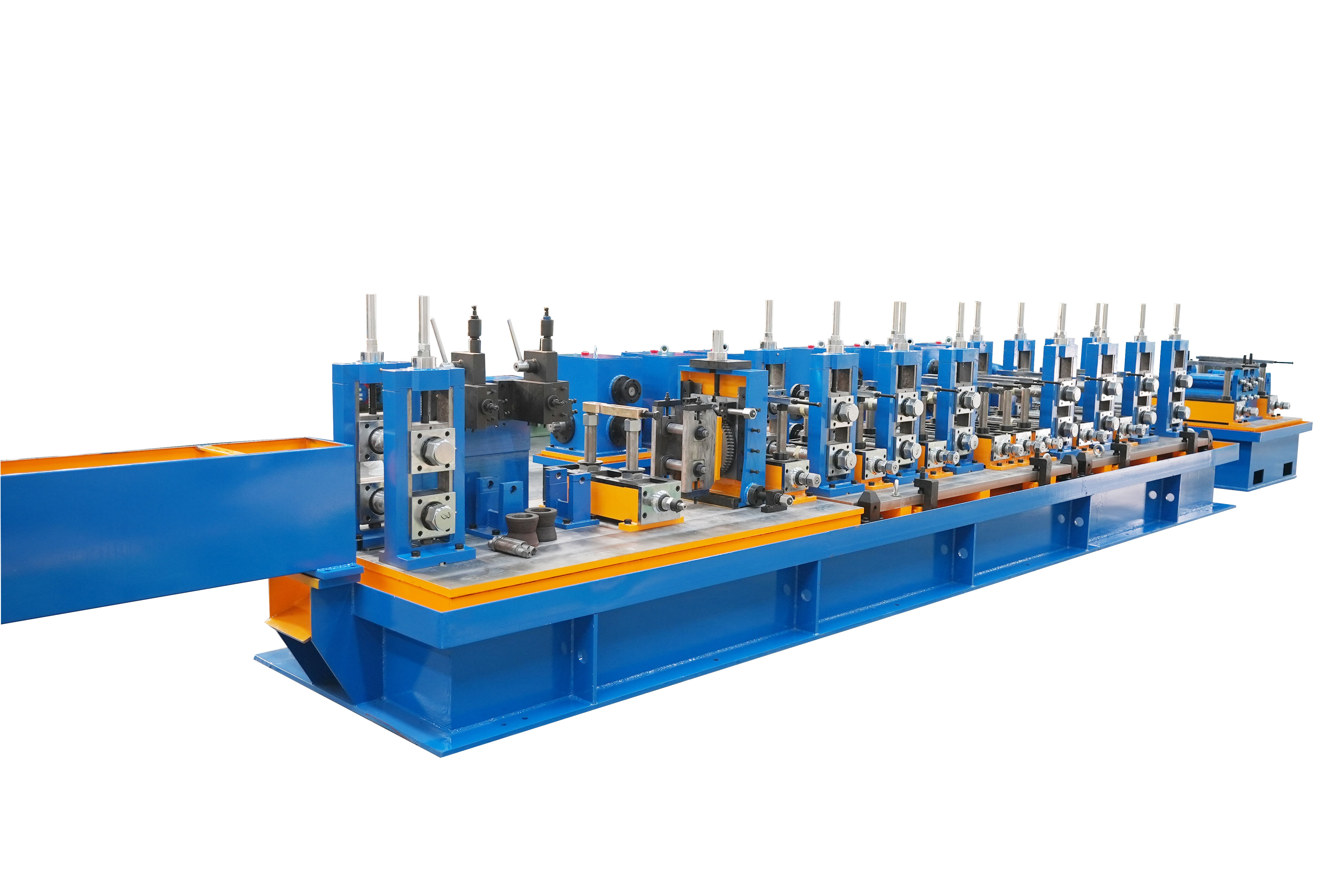

Here you go, what is mean by auto steel pipe making machine? Automatic steel pipe manufacturing machines are automatic machines that manufacture steel pipes from start to end. Such lines usually consist of: entry unit, welding section, sizing mill and flying shear. The machine will have to utilize the steel strips or coils after twisting them by the steps and then shaping them into pipes with different specifications and sizes.

Now coming towards the types of auto steel pipe making machine, they are further classified on the basis of their application areas. Some machines are used for making seamless pipes and others are for weld-ed pipes, etc. A pipe is selected based on its intended use and the volume (quantity) of production requirements, as well as the type of machinery chosen.

Advantages of Automatic Steel Pipe Production Line

Assists in using auto steel pipe making machine as a manufacturer.

Automated machines work faster and effectively handle a typical human machine operations, thus increasing the production throughput in lesser time. So, it aids you in reducing lead time & serving your customers in a better way.

Improved Accuracy and Uniformity– Every pipe that undergoes automated manufacturing will have the same quality standard applied to every piece. These machines offer an extremely high level of precision in the production process, allowing the quality of the end product to exhibit a uniformity that is in alignment with industry specifications.

Low Cost, Low Labor Effort and Maintenance: Because automatic exception management automation leads to low labor levels and low effort level in production. This reduces manpower cost but enables the man force to concentrate on the high value work like quality checking, machine maintaining etc.

More Safety Features: Modern day equipment they use for manufacturing automotive metal pipes are designed to avoid operator contact with danger by incorporating safety features. Machines that take people out of harm's way — away from the most dangerous tasks and environments — contribute to a safer workplace.

Deploying Automated Steel Pipe Manufacturing Equipment

More about working of auto steel pipe making machine, just its depends as compared with the other factory, so its all come here that manufacturer gonna to decide what he or she have to go through with the production and which machine going to be fit with the factory. Factors such as how many pipes you anticipate making, what types of pipes you will be producing, and your budget must be weighed carefully.

After choosing the machine, you should ensure that the machine should function as well as integrate it with the existing job low. It could mean changing existing processes to accommodate the new equipment, for example. Also, the employees have to be trained to operate the machine, repair of the machine, maximize the utilization of the machine, and prevent disruption in the flow of work.

Conclusion

An auto steel pipe making machine can change your production process and even decrease the entire process cost while increasing the quality and quantity of the final output. Automation can also assist manufacturers in keeping up with an ever evolving industry. As technology continues to evolve — Steel pipe making really does have great prospects for the future for those from within the market prepared to embrace and develop these types of technologies or Products.