Introduction

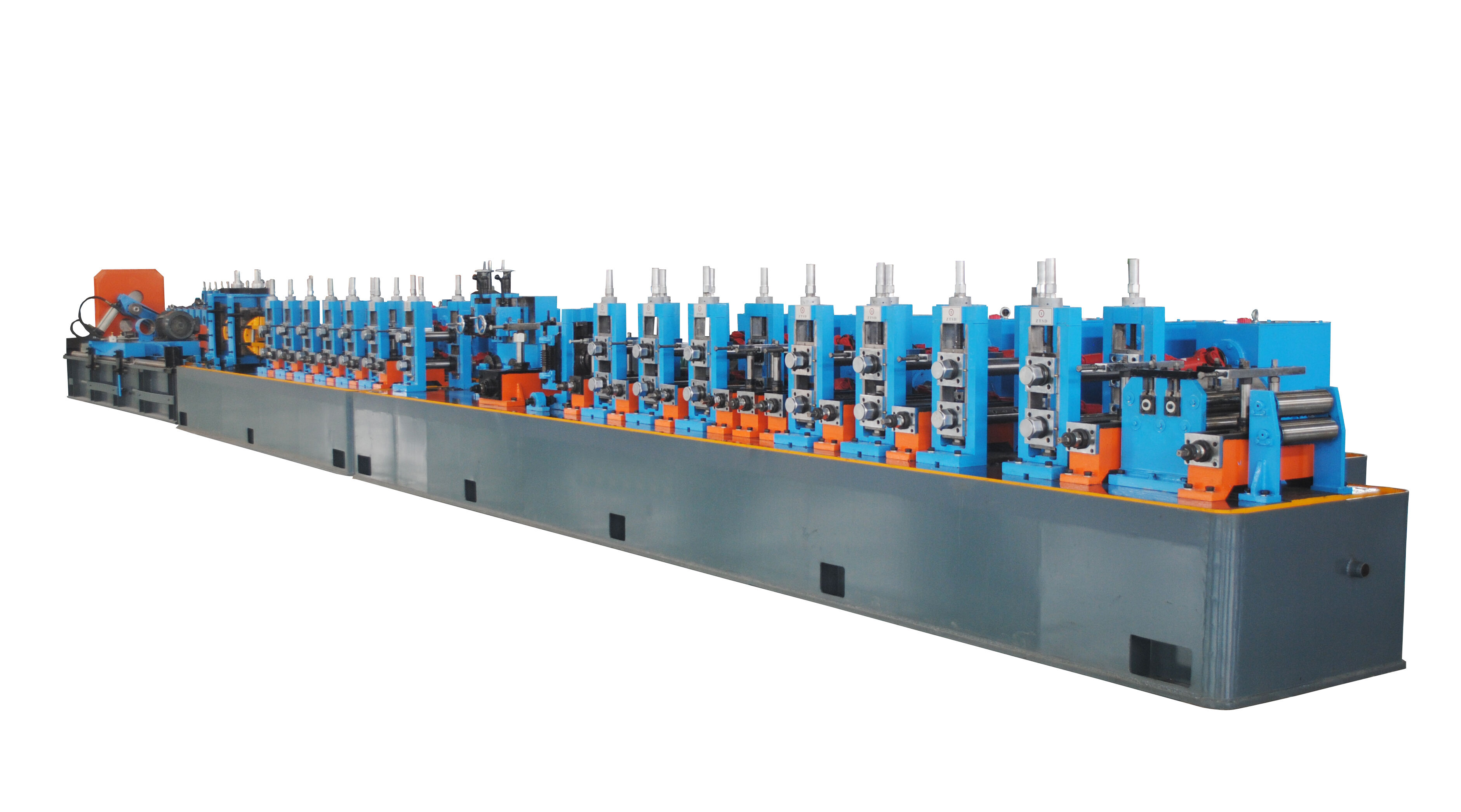

Brief description:

HG32x1.5:High frequency welded pipe production line is used to manufacture welded steel pipe of Φ10mm-Φ32mm,thickness 0.5-1.5 mm, square pipe 10x10-20x20 and Rectangular pipe 20x40mm, thickness 0.4-1.5mm . After we absorbed advanced pipe making technology from all over world, our innovative designed production line and each single unit of the production line is not only economical but also practical.

Product parameters:

(1)Raw material | |

Material Quality |

Q195、Q235B、Q355B、Galvanized Steel、MS、CR、HR |

Mechanical properties |

σb≤500Mpa,σs≤325MPa |

Strip Width |

40-80mm |

Strip Thickness |

0.5-1.5mm |

Coil ID |

Φ508-610mm |

Coil OD |

Φ1200mm-2100mm |

Coil Weight |

2T |

(2)Finished Product Size and purpose | |

Pipe Size |

Round Pipe: φ10-φ32 mm T:0.5-1.5 mm Square Pipe:10x10-20x20mm T:0.5-1.5 mm |

Length |

4-6m |

Application |

Structure |

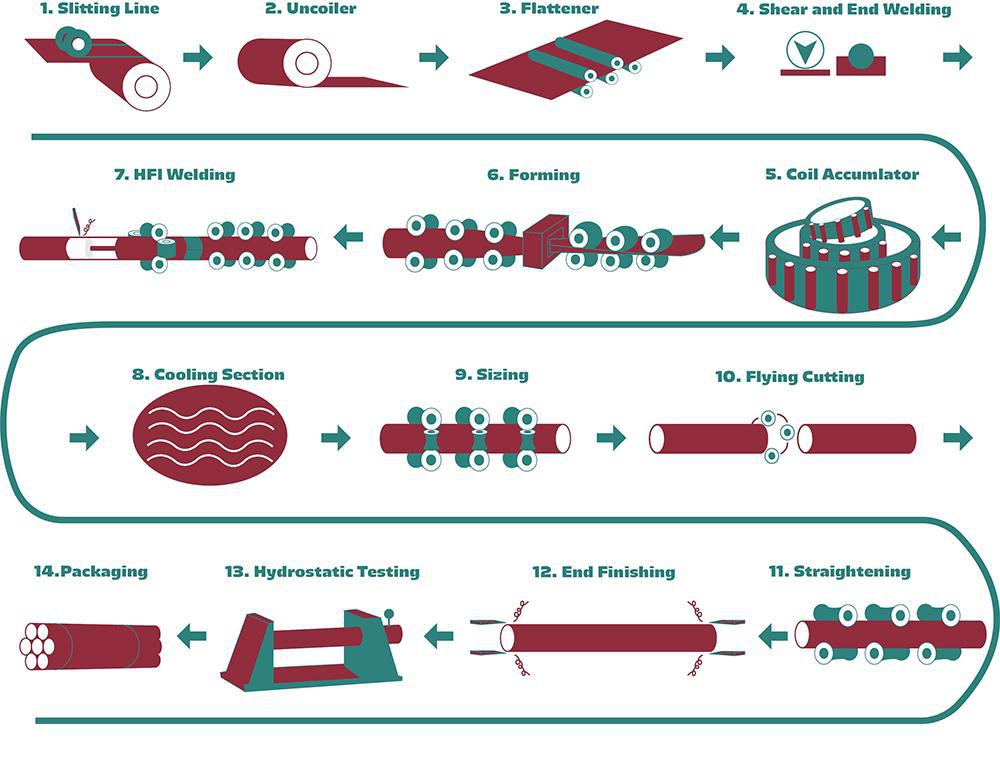

(3)The working process of the production line | |

| |

(4)This line contain | |

Uncoiler |

Expansion and cantilever mandrels. Contains two main parts: main body and the fixed base. Equipped with pneumatic system to satisfy the needs of expanding, contracting and braking of the mandrels. Mandrel consists of four-bar linkages that could move radially at the same time. The four-bar linkages in two groups are fitted on two shafts respectively. Powered by air cylinder, they expand and contract radially. |

Automatic shear and welder |

It is used to cut the irregular ends of the strips and then connect the strips by welding. So it can let the line runing without stop when the before coil finish |

Spiral accumulator |

This machine is between shear welder and host (forming sizing mill) ,use for after a roll of strip steel are used up, before the next roll strip since prepared from uncoiling, shearing and butt welding time to ensure that the host (forming sizing mill) continuous production and store enough strip steel. |

Forming and sizing mill |

Forming & Sizing Mill adopts roller type forming principle and high-frequency induction welding. The strip is fed into the forming machine by the feeding device in the mill and the forming roller continuously rotate and press the strip into the required shape. Due to the skin and the kindred effect, the high-frequency current is concentrated on the weld joint that is heated rapidly and reaches the welding temperature. The tube seam is welded under the pressure of squeeze rollers. The finished welded tube with required size can obtained after the cooling, sizing and primary straightening. |

Cutting saw |

It is used to precisely cut the pipe to length automatically under the condition that the pipe continuously delivered from the mill at high speed. |

150 kw Hifrequency Welder |

Weld the seam |

Runout Transit table |

Transit the finished pipe to the collection table |