pembuatan tabung

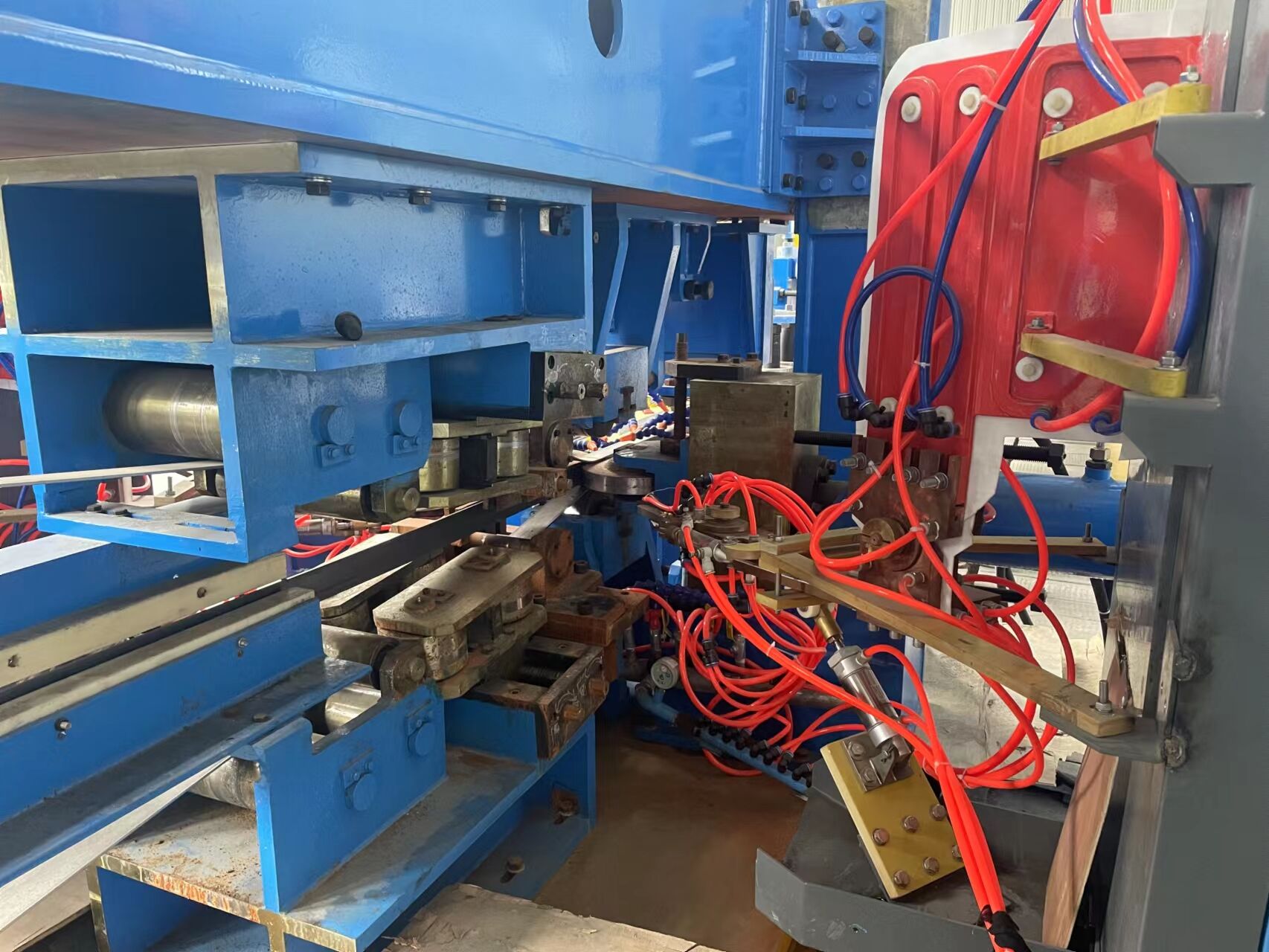

Proses pengelasan resistansi listrik (ERW) digunakan pada pabrik tabung ERW, peralatan canggih ini dibuat dengan teknologi pemrosesan yang terampil untuk manufaktur tabung baja dengan presisi tinggi. Fungsi utama dari pabrik tabung ERW mencakup banyak tahap pemrosesan: pembentukan dan pengelasan, pemotongan hingga dimensi atau panjang akhir. Lembaran logam dari berbagai logam dapat digunakan dalam unit ini. Fitur teknologi dari pabrik ini termasuk teknologi pengelasan resistansi listrik, yang memanaskan logam tepi pabrik hingga titik lebur. Kemudian, di bawah tekanan, mereka disatukan membentuk pengelasan kontinu. Hasilnya adalah integritas struktural yang tinggi dan tabung yang tahan lama. Pabrik tabung ERW mengandung semua teknologi terbaru mulai dari sistem kontrol untuk memastikan akurasi dimensi yang tepat, dan peralatan kontrol kualitas. Itu membuat produk ini cocok untuk berbagai aplikasi, termasuk konstruksi, otomotif, HVAC, dan industri furnitur di mana tabung tanpa sambungan harus cukup kuat untuk menahan beban berat.