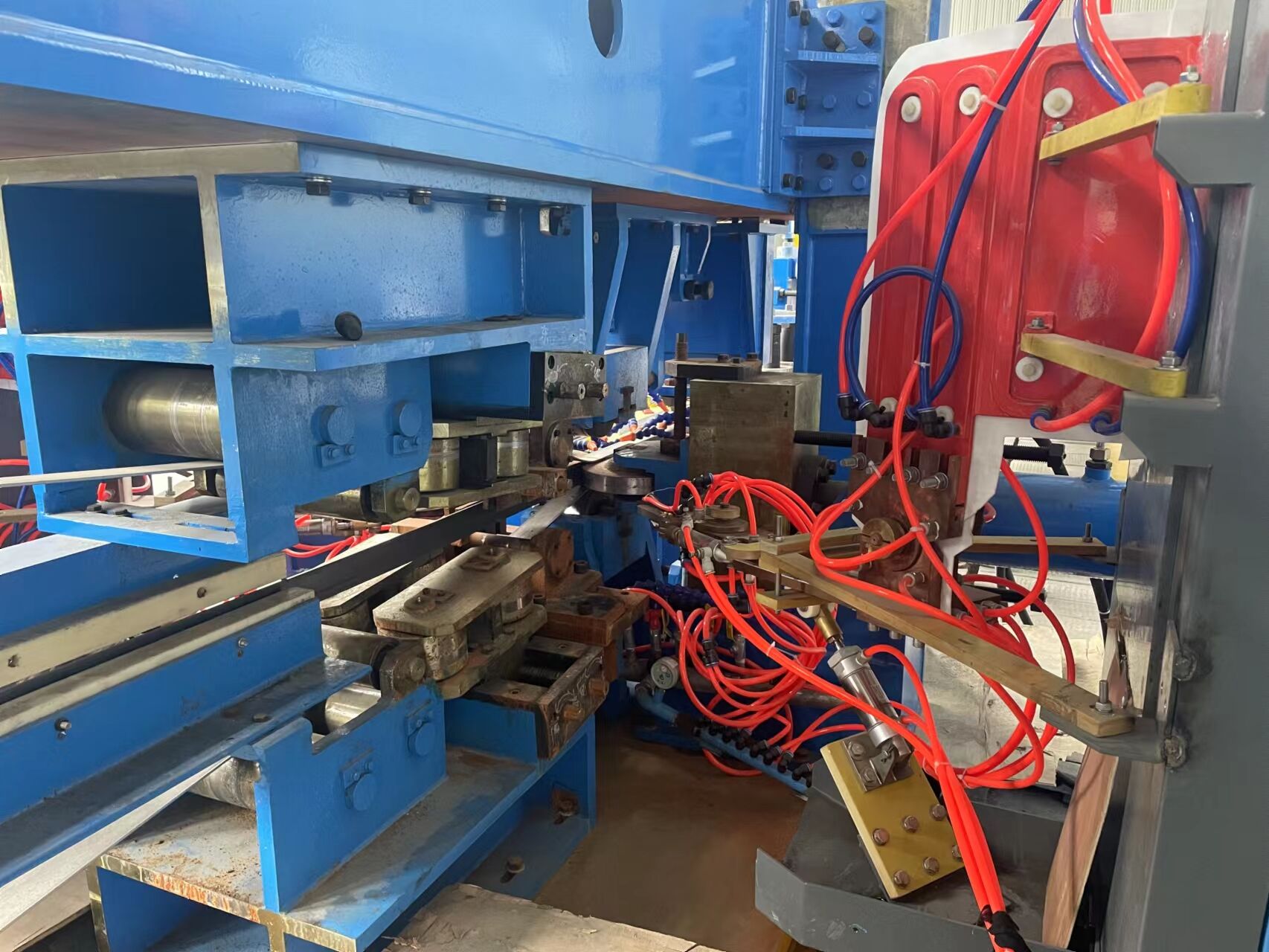

roll forming machine

A novel piece of machinery is the roll forming machine. It was created to make large quantities and uniform parts with a consistent cross-section that are relatively long in length. The use of the roll forming process imparts various shapes to plain metal strips. A number of rollers progressively bend and fold heating the material to the shape desired. This machine is full of technological features that make it easier to use. These include adjustable spacing between rollers for different profiles, automatic control bellows or diaphragms which satisfy both accuracy and repetition between rollers and variable speed capabilities to give production the necessary flexibility. This machine has a wide range of applications in such industries as building materials, automotive industry and aerospace. It is widely used to make things like I-beams and channels, as well as frames for steel pipes.