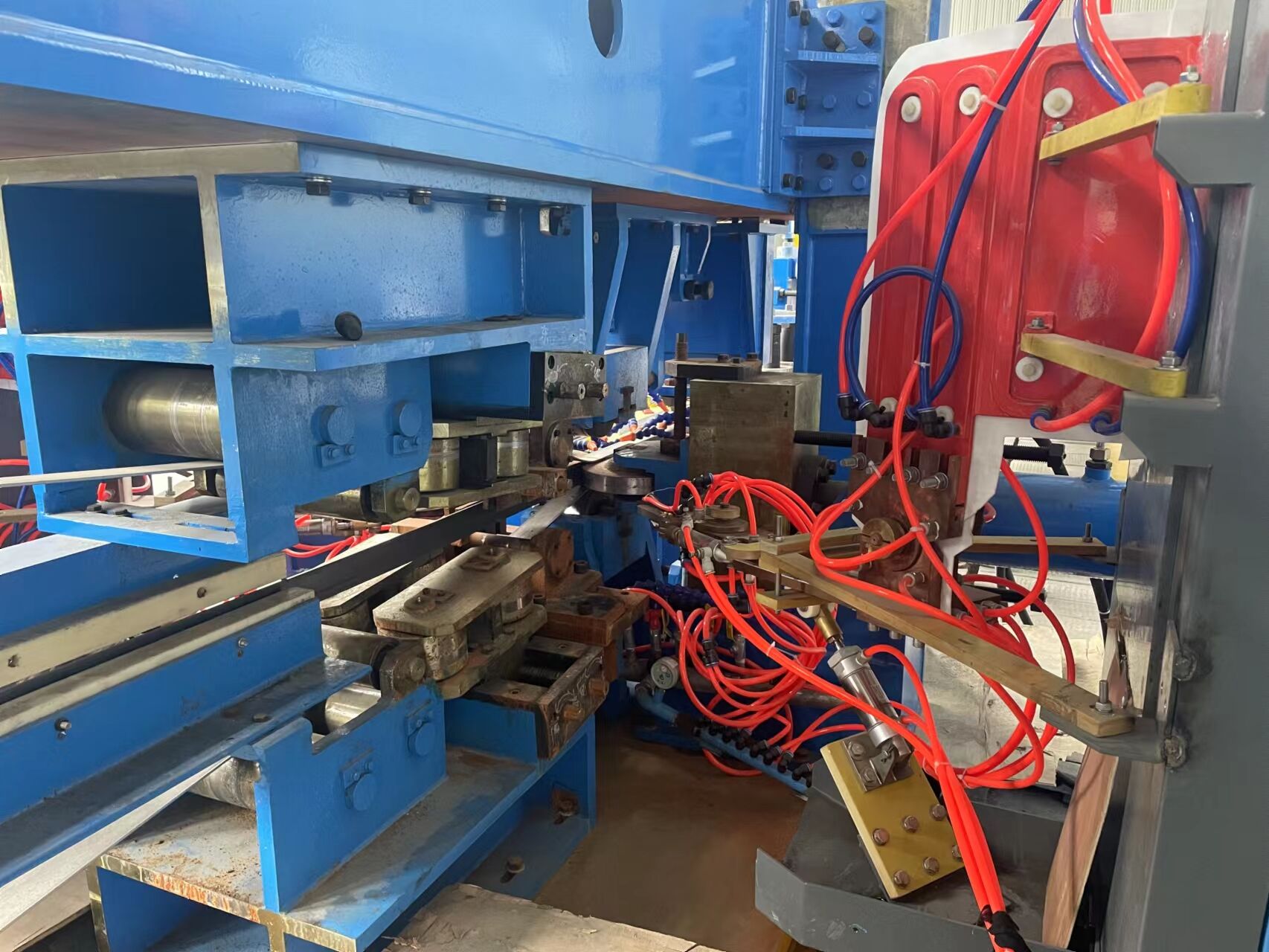

slitter rewinder used manufacturer

The slitter rewinder manufacturer provides machinery to suit the needs of precision industry-users. This kind of machine is necessary for converting big rolls into little ones or even small strips that can be useful to anyone who needs it whether they are in-home use or for business application of take-away food wrapping materials. With the invention of this sophisticated equipment, which provides such an extraordinary degree of accuracy as well as great speed and efficiency in doing its main work-slitting material to desired width – also winding said materials up once again onto a fresh core, there will be no more waste whatsoever. Equipment Specifications The slitter rewinder is a machine designed to carry out its work in different angles and with speed. To this end it features automatic control systems, precise tension control, and speeds that can be set steplessly. All these developments serve to ensure that papers, film, foil, etc. all pass through the machine with an even quality stamped upon them at every step in production line so as not only must nothing go wrong but even when things are running smoothly nothing is wasted. The Uses Of The Blogs For Their Business Header (Blogs) The slitter rewinder can be found in a wide variety of industries such as packaging, printing and converting. Furthermore, many other industries contribute to the field by their own various names for it. Prdouctivity & Cost Efficiency The slitter rewinder is indispensable to those whose aim is high productivity and cost efficiency. First, second or third hand users can make use from our reconditioned machines.