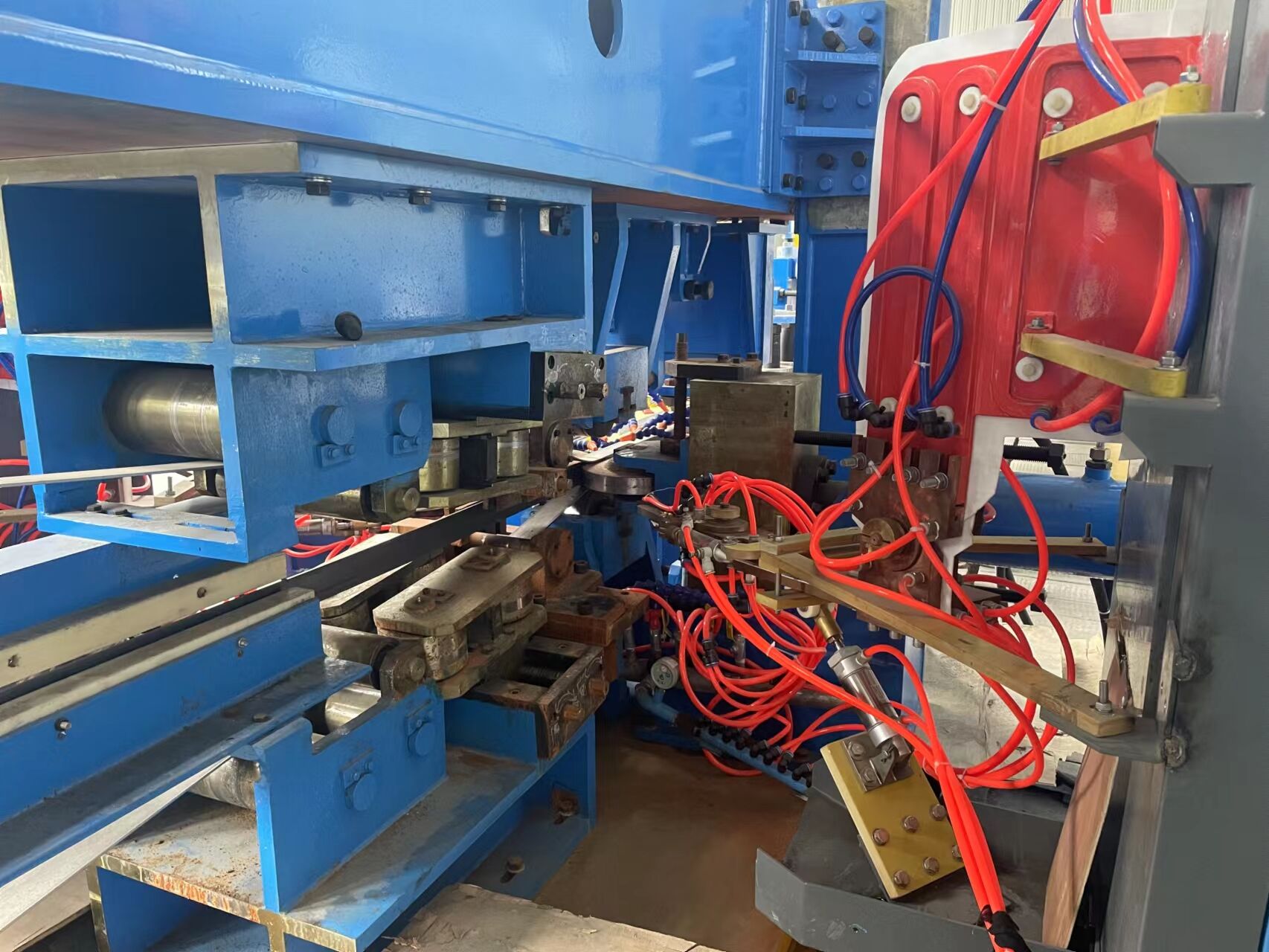

steel slitting machine

The steel slitter is a precision tool used in the efficient processing of metal coils, sheets. Its main function is to slit large steel coils into various widths localizated on shape. It is indispensable in manufacturing, and the metal processing industry thus cannot do without this mighty little thing.Bilghtly re-designed the previous steel slitter, it adopts the latest technology, such as programming of controls for precision slitting, most user-friendly operating system available today which accepts international programming languages for selection in different countries :- Chinese & Thai among others.The technical features of Y- 02 steel slitter include programmable controls of cut width, interchangeable rollers to suit various materials thicknesses and automatic lubricating systems on the bearings which prolong life and make maintenance very easy.The user-friendly CNC As the operator is faced with ever-increasing amounts of information, the man-machine interface was developed to reduce tasks and provide comprehensive help. The full colour or touch screen control system also ensures that all relevant datum is input at an appropriate time making quality a promise guaranteed up front in process automation which guides users to successful cutting process performance with ease for each their specific needs.

This machine is specifically used for precision high-volume steel cutting in the automobile, construction and electronics industries.