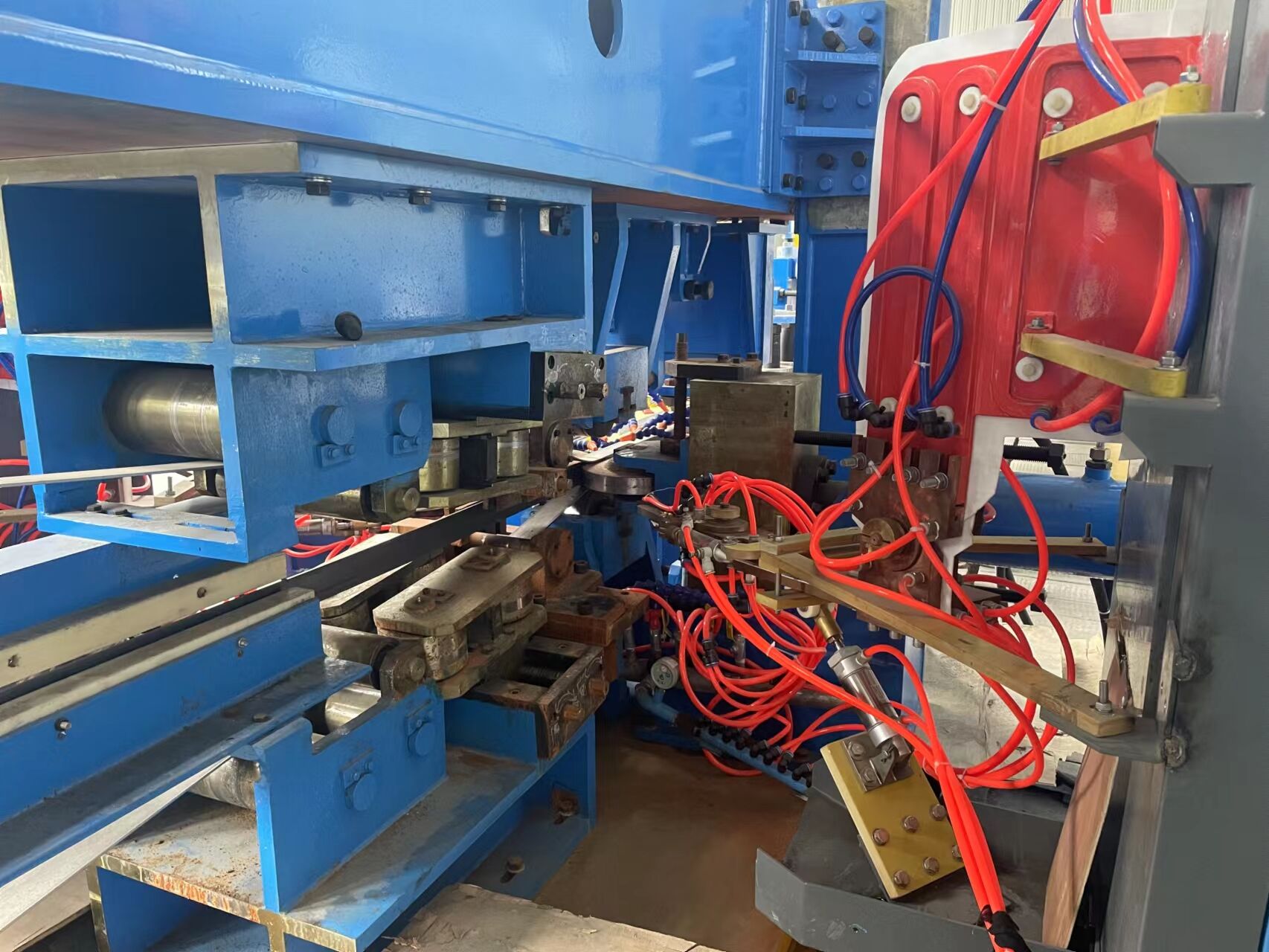

tube mill production line

Ang paggamit ng mga state-of-the-art na sistema upang makagawa ng ganitong anyo ng welding tube ay isinasaalang-alang sa amin. Ito ay mahusay na nilagyan upang gumanap ng maraming mga function, kabilang ang uncoiling, pagbuo, welding, pagputol ng tela gilid trimming at pag-aayos metal na mga strip sa Ang pagpapakilala ng mga teknolohikal na tampok tulad ng mga sistema ng tumpak na kontrol ng CNC, mekanikal na automation, variable speed drive system upang mapanatili ang paggamit ng materyal na manipis at malinis; nangangahulugan na kami ay nagpapatakbo sa isang mahigpit sa kapaligiran na paraan habang pinapanatili ang mataas na mga antas ng produksyon. Bukod dito, ang ganitong uri ng linya ng produksyon ay maaaring mag-asikaso ng parehong magaan at mabibigat na pag-aari ng trabaho. At ito ay may isang hanay ng mga function na kinabibilangan ng welding steel tube perpetual feeder shearing machines na maaaring makamit ang parehong pagganap bilang isang slitter nang hindi kailanman slitting kahit sino sedan.Building at konstruksyon, automotive supply at exhaust pipe, pati na rin ang mga pangangailangan ng mga industriya ng furniture at