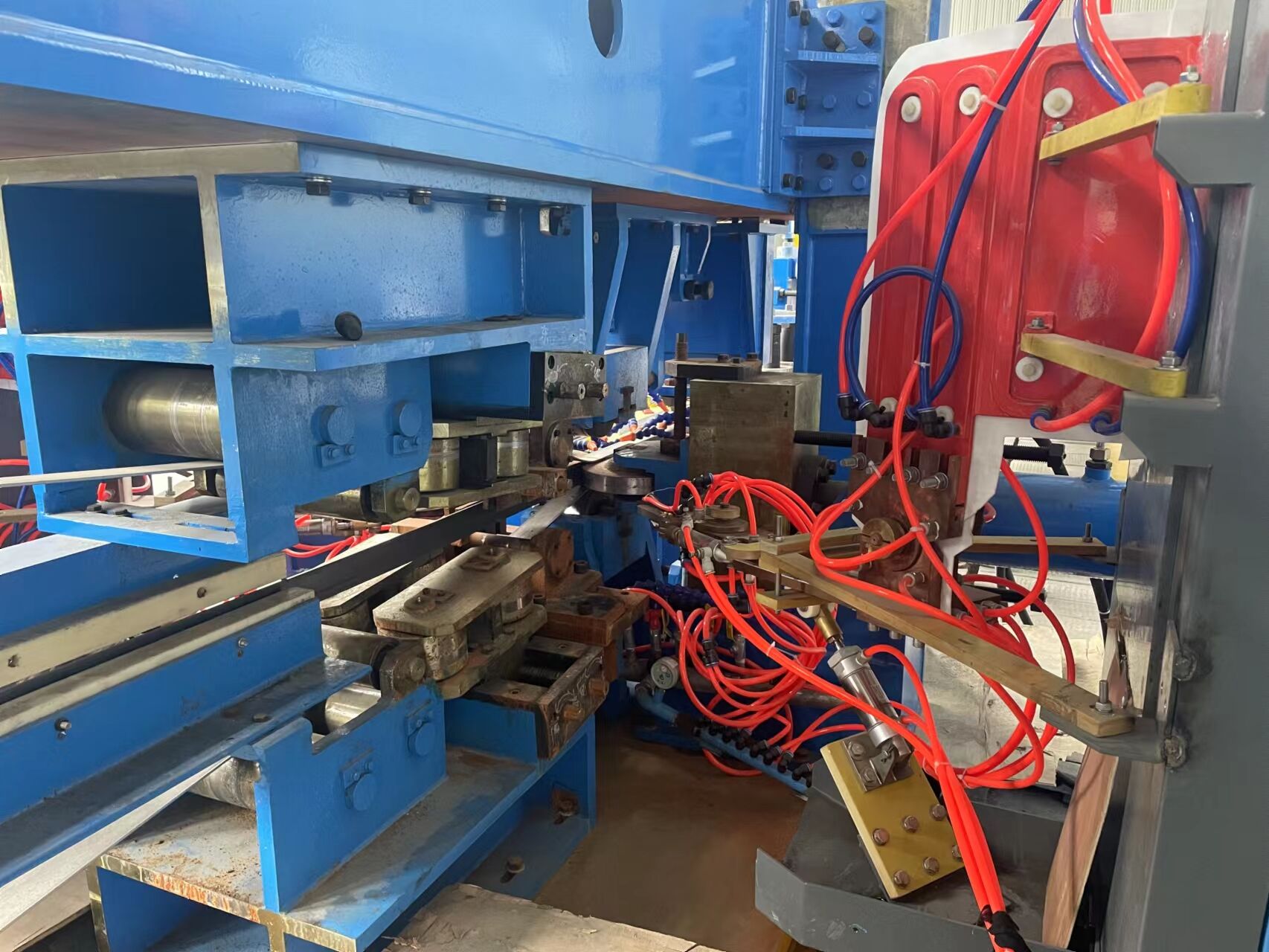

c purlin forming machine

The Purlin Machinery is a state-of-the-art that offers ultra-high processing efficiency metal forming equipment. Its main function is to take metal strips and bend them into c-shaped purlins. In this way, they can be used as part of buildings for building roofs, ceilings or bridges for carrying beam loads. This machine offers a broad range of control features, such as a user-friendly operation interface, precise servo motor control and automatic material feeding and cutting systems which help ensure product consistency. It is a machine with high precision, And stable and reliable operation. The machine may be used in many contexts, such as if you want to produce a roof truss and then from there go on to make an entire house or other building out of it. With advanced technology and robust construction, the c purlin forming machine speeds production of metal structures at greatly reduced cost.