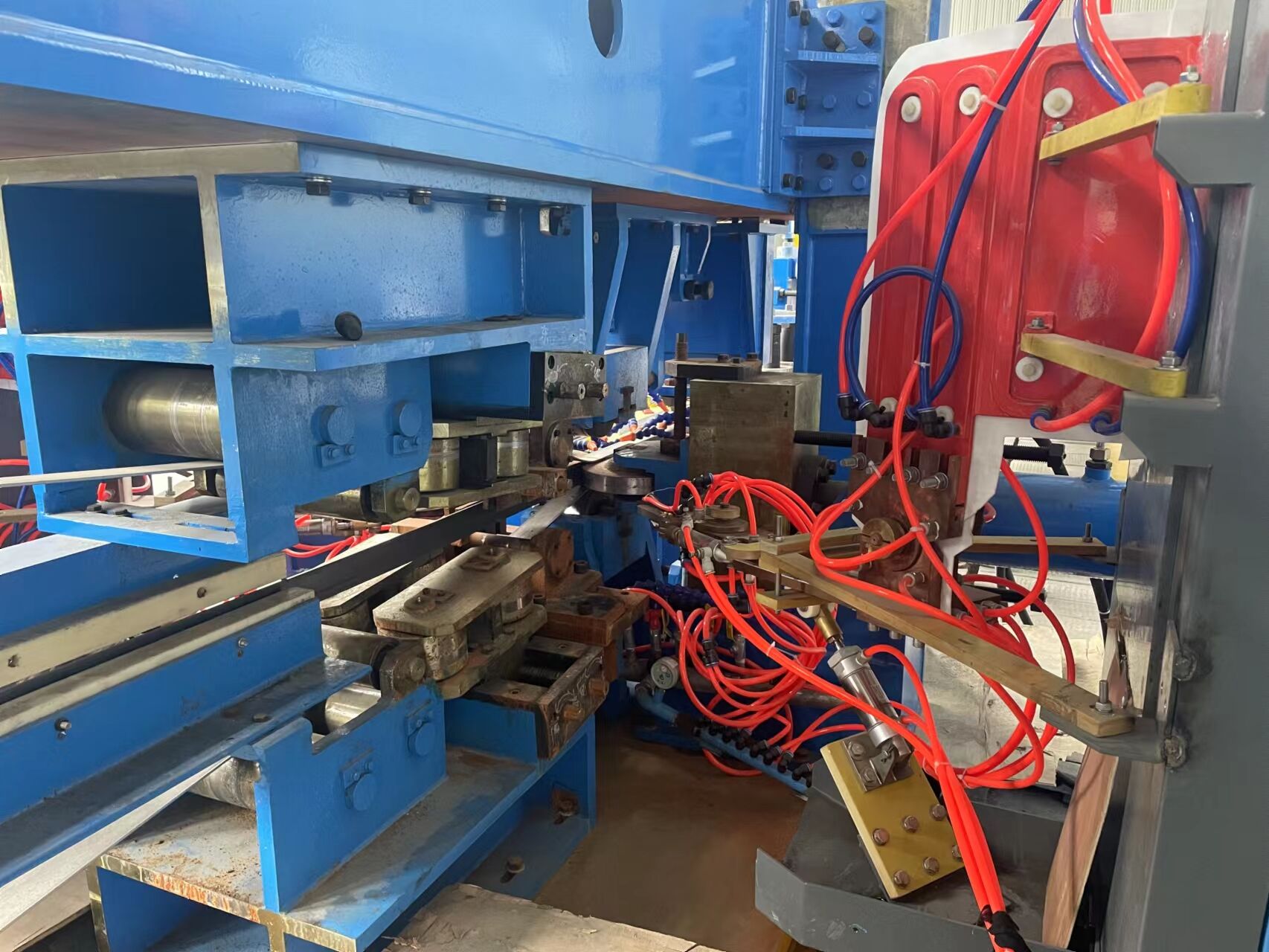

c purlin roll forming machine

In order to manufacture C purlins used in construction efficiently and cheaply on a large scale, the whole length of line is clas- sified as a metal forming machine. Its four major functions consist of decoiling, leveling, punching, cutting and shaping metal strips into finished C purlin sections that can be used in buildings constructed using steel frame structures. Which method does these machines take to match parts together? Technically, there are a range of features such as automated control systems publicity, the closed-loop speed control system powder sprays barrel-shaped particles high precision rollers powered by variable-speed drives fully automated oil and pressure system Whole overhead roll sheet roll forming unit sales output value accounted for 25% of Taiwan's total machinery products exports that year This machine is suitable for a wider range of applications than any other such devices produced in this factory. It can be applied to the manufacturing of roof trusses, wall frames and joists on large concrete buildings as well as in more common wood timber buildings.