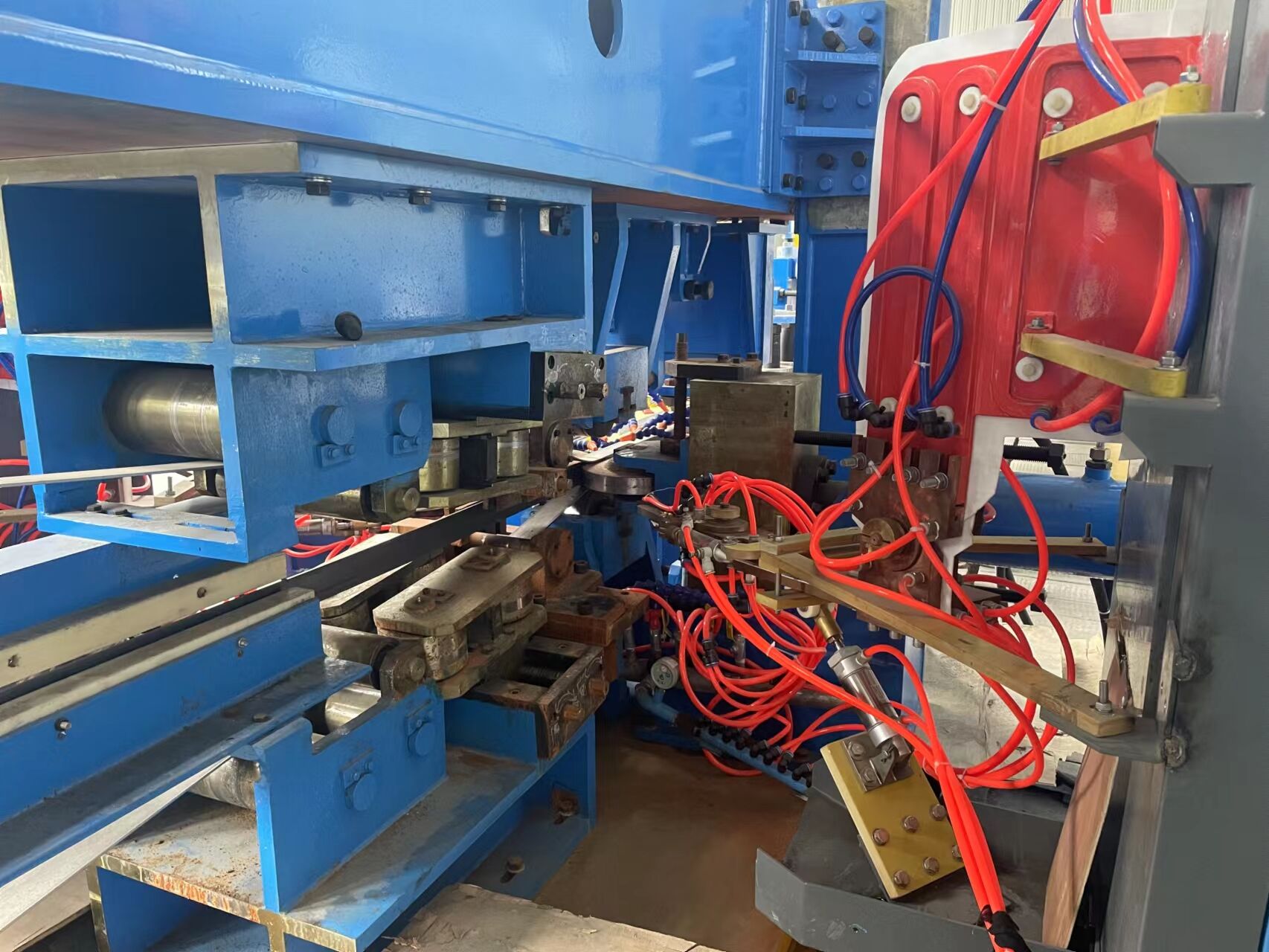

coil slitting machine manufacturer

The company is a well-known supplier of metal processing industry, specializing in high-quality machinery valued for its role in material transformation.There are several functions for the coil slitting machine. The first and foremost application is to cut a large metal coil into smaller pins at high precision and high speed technological features include automated controls, variable speed drives, and user friendly programable slit arrangements to make the right flexible for different materials types and thicknesses.Everywhere from automotive, construction, packaging, household appliances--the uses of coil slitting machine are extensive.The robust design and advanced features make them indispensable to the maximum production efficiency and yield.