slitting rewinding manufacturer

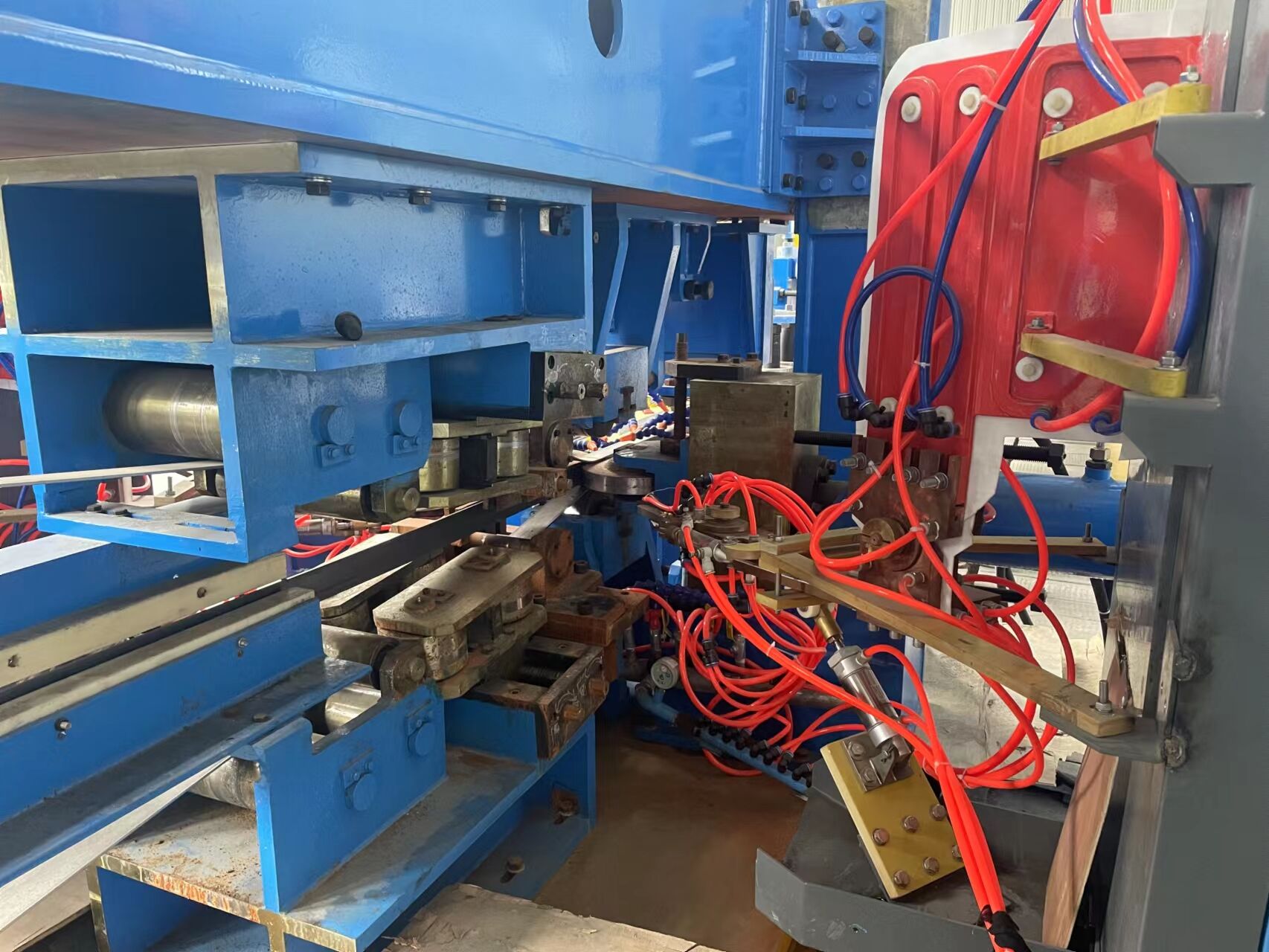

At the forefront of material processing, our slitting rewinding manufacturers entail precision and reliability in converting large roils of material into narrower widths, meanwhile rewinding them into smaller, more manageable roils. The main functions of these slitting and rewinding machines are to cut the material into a required width and then wind it onto another core that can be used in many industries. Technological features such as automatic control systems, precision cutting blades and variable speed control ensure high-yield production with low waste. These machines are versatile, serving a wide range of applications including the paper, film and plastic, photographic processes, mills where precise material handling and efficient production are essential.